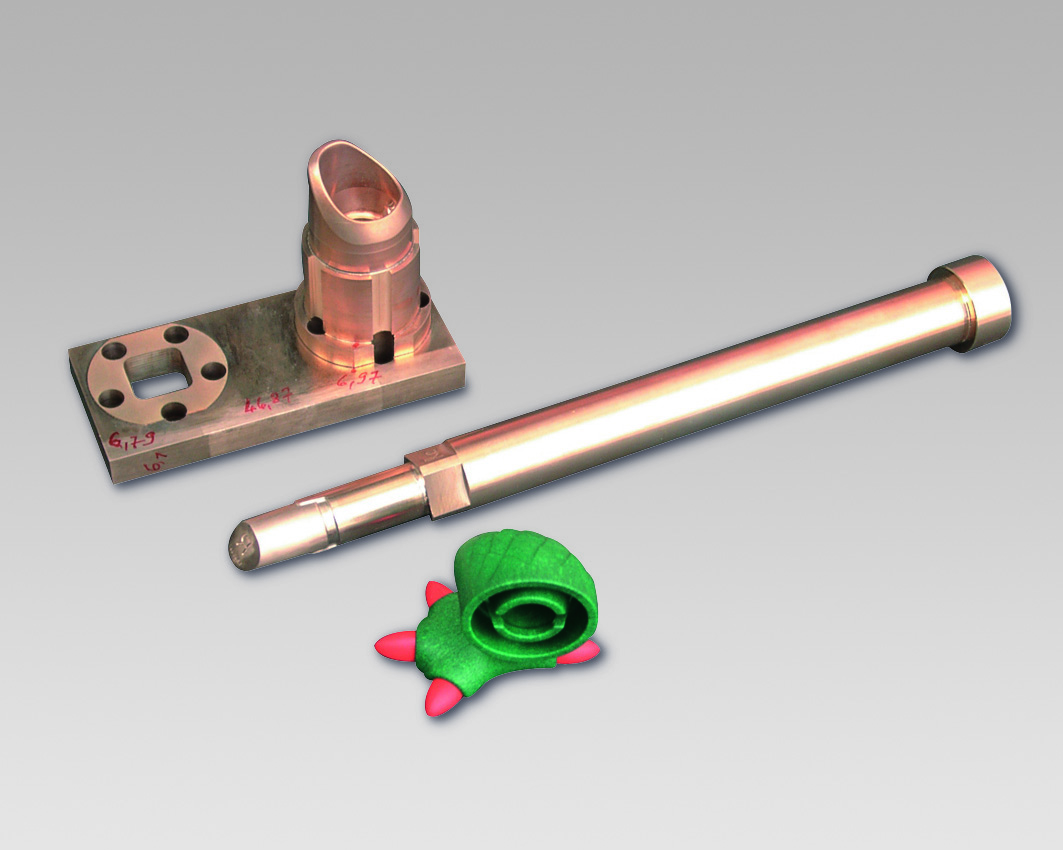

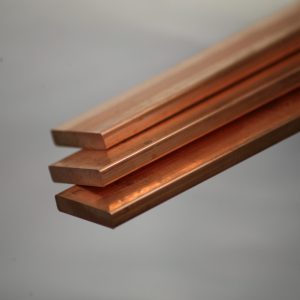

Description

Chemical composition (nom.)

Cu Rest.

Co 0.8-1.3 %

Ni 0.8-1.3 %

Be 0.4-0.7 %

Max impurities

Other. 0.5 % max.

Physical properties

Mean linear coefficient of thermal expansion (10-6/K): 17

Thermal conductivity (W/mK): 250

Electrical conductivity (m/W ohm mm2): 26-30

Elastisity modulus E (kN/mm2): 135

Density (g/cm3): 8.8

Mechanical properties

Yield strength (Rp N/mm²): 496-550 N/mm²

Tensile strength (Rm N/mm²): 700-900 N/mm²

Elongation in % A5: 10.0-17.0%

Hardness/Brinell: 217-240 HB

Hardness/Rockwell: 100 HRB